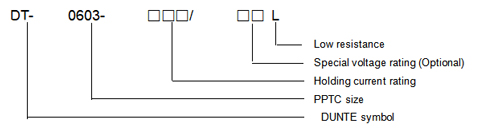

SMDDT-0603 Low 系列

|

Features ▶Ultra low resistance ▶RoHS compliant and lead-free ▶Halogen-free ▶Fast response to fault current ▶Symmetrical design |

Applications ▶USB port protection - USB 2.0, 3.0&OTG ▶Li-ion/Li-Polymer battery packs ▶PDAs / digital cameras ▶Computer periperals ▶PC motherboards-plug and play protection |

产品规格书

产品规格书

| Model | I-hold | I-trip | Vmax | Imax | Pd typ | Max. Time to trip | R0 min | R1max | |

| Current | Time | ||||||||

| (A) | (A) | (Vdc) | (A) | (W) | (A) | (Sec.) | (Ohm) | (Ohm) | |

| DT-0603-050L | 0.50 | 1.00 | 9 | 50 | 0.50 | 8.00 | 0.60 | 0.090 | 0.250 |

| DT-0603-050/12L | 0.50 | 1.00 | 12 | 50 | 0.50 | 8.00 | 0.60 | 0.090 | 0.250 |

| DT-0603-075L | 0.75 | 1.50 | 9 | 50 | 0.50 | 8.00 | 1.00 | 0.070 | 0.220 |

| DT-0603-075/12L | 0.75 | 1.50 | 12 | 50 | 0.50 | 8.00 | 1.00 | 0.070 | 0.220 |

| DT-0603-100L | 1.00 | 2.00 | 9 | 50 | 0.50 | 8.00 | 2.00 | 0.040 | 0.150 |

| DT-0603-100/12L | 1.00 | 2.00 | 12 | 50 | 0.50 | 8.00 | 2.00 | 0.040 | 0.150 |

| DT-0603-125L | 1.25 | 2.50 | 9 | 50 | 0.50 | 8.00 | 3.00 | 0.030 | 0.120 |

| DT-0603-125/12L | 1.25 | 2.50 | 12 | 50 | 0.50 | 8.00 | 3.00 | 0.030 | 0.120 |

| DT-0603-150L | 1.50 | 3.00 | 9 | 50 | 0.50 | 8.00 | 4.00 | 0.020 | 0.080 |

| DT-0603-150/12L | 1.50 | 3.00 | 12 | 50 | 0.50 | 8.00 | 4.00 | 0.020 | 0.080 |

| DT-0603-175L | 1.75 | 3.50 | 9 | 50 | 0.50 | 8.00 | 5.00 | 0.015 | 0.070 |

| DT-0603-175/12L | 1.75 | 3.50 | 12 | 50 | 0.50 | 8.00 | 5.00 | 0.015 | 0.070 |

| DT-0603-200L | 2.00 | 4.00 | 9 | 50 | 0.50 | 8.00 | 5.00 | 0.012 | 0.065 |

| DT-0603-200/12L | 2.00 | 4.00 | 12 | 50 | 0.50 | 8.00 | 5.00 | 0.012 | 0.065 |

| DT-0603-250L | 2.50 | 5.00 | 9 | 50 | 0.50 | 8.00 | 5.00 | 0.010 | 0.060 |

| DT-0603-250/12L | 2.50 | 5.00 | 12 | 50 | 0.50 | 8.00 | 5.00 | 0.010 | 0.060 |

| DT-0603-260L | 2.60 | 5.20 | 9 | 50 | 0.50 | 8.00 | 5.00 | 0.008 | 0.055 |

| DT-0603-260/12L | 2.60 | 5.20 | 12 | 50 | 0.50 | 8.00 | 5.00 | 0.008 | 0.055 |

| DT-0603-300L | 3.00 | 6.00 | 9 | 50 | 0.50 | 8.00 | 5.00 | 0.008 | 0.050 |

| DT-0603-300/12L | 3.00 | 6.00 | 12 | 50 | 0.50 | 8.00 | 5.00 | 0.008 | 0.050 |

I-hold: Holding Current: maximum current at which the device will not trip in 25℃ still air.

I-trip: Tripping Current: minimum current at which the device will trip in 25℃ still air.

Vmax: Maximum voltage device can withstand without damage at rated current(Imax).

I max: Maximum fault current device can withstand without damage at rated voltage(Vmax).

Pd typ:Typical power dissipated from device when in the tripped state at 25℃ still air.

R0 min:Minimum resistance of device in initial (un-soldered) state.

R1 max:Maximum resistance of device at 25℃ measured one hour after tripping or reflow soldering of 260℃ for 20 sec.

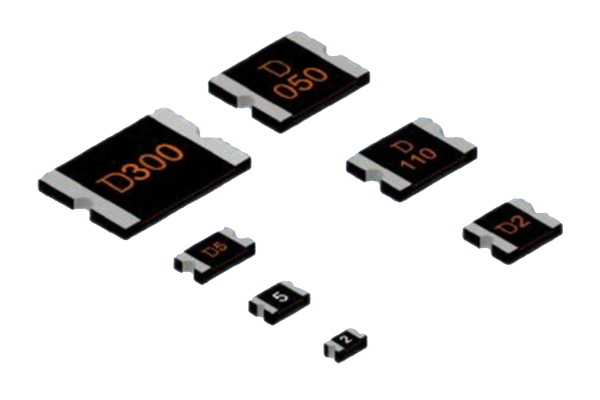

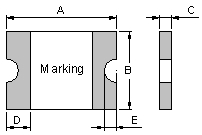

2、Product Dimensions(mm)&Marking :

| Model | A | B | C | D | E | Marking | ||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | ||

| DT-0603-050L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | C |

| DT-0603-050/12L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | C |

| DT-0603-075L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | D |

| DT-0603-075/12L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | D |

| DT-0603-100L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | E |

| DT-0603-100/12L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | E |

| DT-0603-125L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | F |

| DT-0603-125/12L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | F |

| DT-0603-150L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | T |

| DT-0603-150/12L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | T |

| DT-0603-175L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | H |

| DT-0603-175/12L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | H |

| DT-0603-200L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | I |

| DT-0603-200/12L | 1.45 | 1.85 | 0.65 | 1.05 | 0.35 | 0.75 | 0.15 | 0.50 | 0.05 | I |

| DT-0603-250L | 1.45 | 1.85 | 0.65 | 1.05 | 0.60 | 1.00 | 0.15 | 0.50 | 0.05 | J |

| DT-0603-250/12L | 1.45 | 1.85 | 0.65 | 1.05 | 0.60 | 1.00 | 0.15 | 0.50 | 0.05 | J |

| DT-0603-260L | 1.45 | 1.85 | 0.65 | 1.05 | 0.60 | 1.00 | 0.15 | 0.50 | 0.05 | K |

| DT-0603-260/12L | 1.45 | 1.85 | 0.65 | 1.05 | 0.60 | 1.00 | 0.15 | 0.50 | 0.05 | K |

| DT-0603-300L | 1.45 | 1.85 | 0.65 | 1.05 | 0.60 | 1.00 | 0.15 | 0.50 | 0.05 | L |

| DT-0603-300/12L | 1.45 | 1.85 | 0.65 | 1.05 | 0.60 | 1.00 | 0.15 | 0.50 | 0.05 | L |

3、Thermal Derating Chart:

| Model | Ambient Operating Temperature | ||||||||

| -40℃ | -20℃ | 0℃ | 25℃ | 40℃ | 50℃ | 60℃ | 70℃ | 85℃ | |

| DT-0603-050L | 0.73 | 0.66 | 0.57 | 0.50 | 0.44 | 0.38 | 0.35 | 0.30 | 0.24 |

| DT-0603-050/12L | 0.73 | 0.66 | 0.57 | 0.50 | 0.44 | 0.38 | 0.35 | 0.30 | 0.24 |

| DT-0603-075L | 1.10 | 0.99 | 0.86 | 0.75 | 0.66 | 0.58 | 0.52 | 0.45 | 0.36 |

| DT-0603-075/12L | 1.10 | 0.99 | 0.86 | 0.75 | 0.66 | 0.58 | 0.52 | 0.45 | 0.36 |

| DT-0603-100L | 1.46 | 1.32 | 1.14 | 1.00 | 0.87 | 0.77 | 0.70 | 0.61 | 0.48 |

| DT-0603-100/12L | 1.46 | 1.32 | 1.14 | 1.00 | 0.87 | 0.77 | 0.70 | 0.61 | 0.48 |

| DT-0603-125L | 1.83 | 1.65 | 1.43 | 1.25 | 1.09 | 0.96 | 0.87 | 0.76 | 0.60 |

| DT-0603-125/12L | 1.83 | 1.65 | 1.43 | 1.25 | 1.09 | 0.96 | 0.87 | 0.76 | 0.60 |

| DT-0603-150L | 2.19 | 1.98 | 1.72 | 1.50 | 1.31 | 1.15 | 1.05 | 0.91 | 0.71 |

| DT-0603-150/12L | 2.19 | 1.98 | 1.72 | 1.50 | 1.31 | 1.15 | 1.05 | 0.91 | 0.71 |

| DT-0603-175L | 2.56 | 2.31 | 2.00 | 1.75 | 1.53 | 1.34 | 1.22 | 1.06 | 0.83 |

| DT-0603-175/12L | 2.56 | 2.31 | 2.00 | 1.75 | 1.53 | 1.34 | 1.22 | 1.06 | 0.83 |

| DT-0603-200L | 2.92 | 2.64 | 2.29 | 2.00 | 1.75 | 1.54 | 1.39 | 1.21 | 0.95 |

| DT-0603-200/12L | 2.92 | 2.64 | 2.29 | 2.00 | 1.75 | 1.54 | 1.39 | 1.21 | 0.95 |

| DT-0603-250L | 3.65 | 3.30 | 2.86 | 2.50 | 2.18 | 1.92 | 1.74 | 1.51 | 1.19 |

| DT-0603-250/12L | 3.65 | 3.30 | 2.86 | 2.50 | 2.18 | 1.92 | 1.74 | 1.51 | 1.19 |

| DT-0603-260L | 3.80 | 3.43 | 2.98 | 2.60 | 2.27 | 2.00 | 1.81 | 1.57 | 1.24 |

| DT-0603-260/12L | 3.80 | 3.43 | 2.98 | 2.60 | 2.27 | 2.00 | 1.81 | 1.57 | 1.24 |

| DT-0603-300L | 4.38 | 3.96 | 3.43 | 3.00 | 2.62 | 2.31 | 2.09 | 1.82 | 1.43 |

| DT-0603-300/12L | 4.38 | 3.96 | 3.43 | 3.00 | 2.62 | 2.31 | 2.09 | 1.82 | 1.43 |

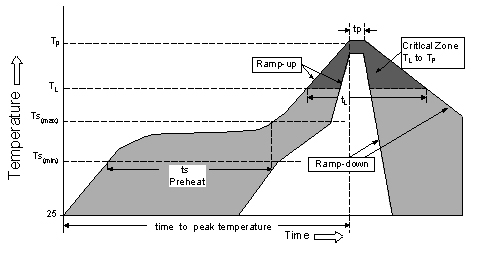

| Profile Feature | Pb-Free Assembly | |

| Average Ramp-Up Rate (Ts(max) to TP) | 3°C/second max | |

| Pre Heat: | Temperature Min (Ts(min)) | 150°C |

| Temperature Max (Ts(max)) | 200°C | |

| Time (Min to Max) (ts) | 60 – 180 secs | |

| Time Maintained Above: | Temperature (TL) | 217°C |

| Temperature (tL) | 60 – 150 seconds | |

| Peak / Classification Temperature (TP) | 260+0/-5 °C | |

| Time within 5°C of actual peak Temperature (tp) | 20 – 40 seconds | |

| Ramp-down Rate | 6°C/second max | |

| Time 25°C to peak Temperature (TP) | 8 minutes Max. | |

◆All temperature refer to topside of thepackage, measured on the package body surface

◆If reflow temperature exceeds the recommended profile,devices may not meet the performance requirements

◆Recommended reflow methods: IR,vapor phase oven,hot air oven,,N2 environment for lead

◆Recommended maximum paste thickness is 0.25mm (0.010inch)

◆Devices can be cleaned using standard industry methods and solvents

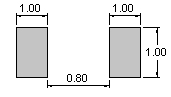

5、Recommended Pad Layout(mm) & Physical Specifications

| Terminal Material | Tin-Plated Nickle-Copper (Solder Material: Matte Tin (Sn)) |

| Lead Solderability | Meets EIA Specification RS186-9E, ANSI/J-Std-002 Category 3. |

6、Environmental Specifications

| Operating Temperature | -40 °C to +85 °C |

| Maximum Device Surface Temperature in tripped State | 125°C |

| Passive Aging | +85 °C, 1000 hours ; ±10 % typical resistance change |

| Humidity Aging | +85 °C, 85 % R.H. 100 hours; ±15 % typical resistance change |

| Thermal Shock | MIL–Std–202, Method 107; +85 °C to -40 °C, 20 times;-30 % typical resistance change |

| Solvent Resistance | MIL–Std–202, Method 215 ; No change |

| Vibration | MIL–Std–883, Method 2007, Condition A; No change |

| Moisture Sensivity Level | Level 2, J–Std–020 |

| Storage Conditions | +30 °C Max. 60% RH Max. Packed in original packaging. |

7、Test Procedures And Requirements

| No. | Test | Test Conditions | Accept/Reject Criteria |

| 1 | R0 min | Resistance measurement at 25℃ | R0min ≤ R ≤ R1max |

| 2 | R1 max | Resistance measurement one hour after post trip | R0min ≤ R ≤ R1max |

| 3 | I-hold | Hold rated current 1800 second without trip, @ 25℃ | No trip |

| 4 | I-trip | Device must trip within 900 second under rated current, @25℃ | trip |

| 5 | Max. time to trip | At specified current, 25 °C | T ≤ max. time to trip (seconds) |

| 6 | trip Cycle Life | Vmax, Imax, 100 cycles | No arcing or burning |

| 7 | trip Endurance | Vmax,Imax 24 hours | No arcing or burning |

| 8 | Solderability | ANSI/J-Std-002 | 95 % min. coverage |

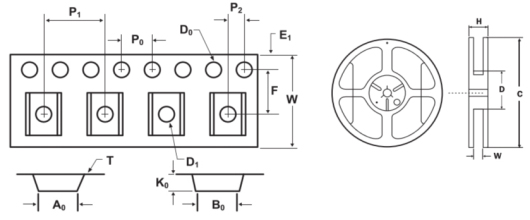

8、Tape and Reel Specifications&Packaging quantity per Reel

| Item | DT-0603-050L DT-0603-050/12L DT-0603-075L DT-0603-075/12L DT-0603-100L DT-0603-100/12L DT-0603-125L DT-0603-125/12L DT-0603-150L DT-0603-150/12L DT-0603-175L DT-0603-175/12L DT-0603-200L DT-0603-200/12L | DT-0603-250L DT-0603-250/12L DT-0603-260L DT-0603-260/12L DT-0603-300L DT-0603-300/12L |

| W | 8.00±0.30 | 8.00±0.30 |

| F | 3.50±0.10 | 3.50±0.10 |

| E1 | 1.75±0.10 | 1.75±0.10 |

| D0 | 1.55±0.05 | 1.55±0.05 |

| D1 | 0.50±0.10 | 0.50±0.10 |

| P0 | 4.00±0.10 | 4.00±0.10 |

| P1 | 4.00±0.10 | 4.00±0.10 |

| P2 | 2.00±0.05 | 2.00±0.05 |

| A0 | 1.10±0.10 | 1.10±0.10 |

| B0 | 1.85±0.10 | 1.90±0.10 |

| T | 0.20±0.10 | 0.20±0.10 |

| K0 | 0.72±0.10 | 0.85±0.10 |

| Leader min | 390mm | 390mm |

| trailer min | 160mm | 160mm |

| Q'ty | 5,000pcs/Reel | 4,000pcs/Reel |

| REEL DIMENSIONS: EIA-481-1 (mm) | |

| C | Ø178±1.0 |

| D | Ø60.2±0.5 |

| W | 9.0±1.5 |

| H | 11.0±0.5 |